A Comprehensive Guide to the Kinds Of Ceramic Coating on the marketplace

Ceramic coatings have actually emerged as an essential remedy throughout different industries due to their special residential properties and applications. As we discover the distinct characteristics and applications of these layers, the implications for efficiency and durability become significantly apparent, raising questions regarding which type may ideal fit your requirements.

Understanding Ceramic Coatings

Ceramic finishings are sophisticated safety solutions that have gotten appeal in various markets, especially in vehicle and aerospace applications. These coatings consist of a fluid polymer that, when treated, forms a long lasting, hydrophobic layer on the surface area of the substratum. This layer gives enhanced resistance to ecological contaminants, UV radiation, and chemical exposure, therefore prolonging the life and aesthetic charm of the underlying material.

The basic component of ceramic coverings is silica, which contributes to their hardness and longevity. The application process usually includes surface preparation, application of the finishing, and healing, which can be accomplished through heat or UV light. As soon as healed, ceramic finishes show outstanding bonding residential or commercial properties, allowing them to adhere highly to a variety of surfaces, including steels, plastics, and glass.

Along with their protective attributes, ceramic finishings additionally supply ease of maintenance. Their hydrophobic nature decreases the adherence of dust and gunk, making cleaning simpler and much less regular. In general, the fostering of ceramic coverings stands for a substantial improvement in surface area security technology, offering both practical and aesthetic benefits throughout numerous sectors.

Types of Ceramic Coatings

Various kinds of ceramic coverings are offered, each developed to meet certain performance requirements and applications - scratch repair sarasota. One of the most typical types consist of:

Silica-based Coatings: These finishings mostly consist of silicon dioxide and are understood for their durability and chemical resistance. They are extensively utilized in automotive and commercial applications.

Titanium Dioxide Coatings: Renowned for their photocatalytic residential or commercial properties, titanium dioxide finishings are typically used in environments where self-cleaning and antifungal homes are desirable, such as in structure materials and vehicle surfaces.

Zirconia Coatings: Characterized by their high-temperature stability and thermal resistance, zirconia finishings are used in applications such as wind turbine engines and high-performance auto parts.

Alumina Coatings: Showing outstanding solidity and thermal security, alumina coverings are regularly made use of in wear-resistant applications, consisting of cutting tools and commercial machinery. - Auto Detailing

Hybrid Coatings: Integrating the residential properties of numerous materials, hybrid finishes supply improved efficiency characteristics, making them suitable for unique and demanding applications.

Each kind of ceramic finish serves distinct objectives, permitting customers to choose the most ideal option based on specific ecological problems and performance requirements.

Advantages of Ceramic Coatings

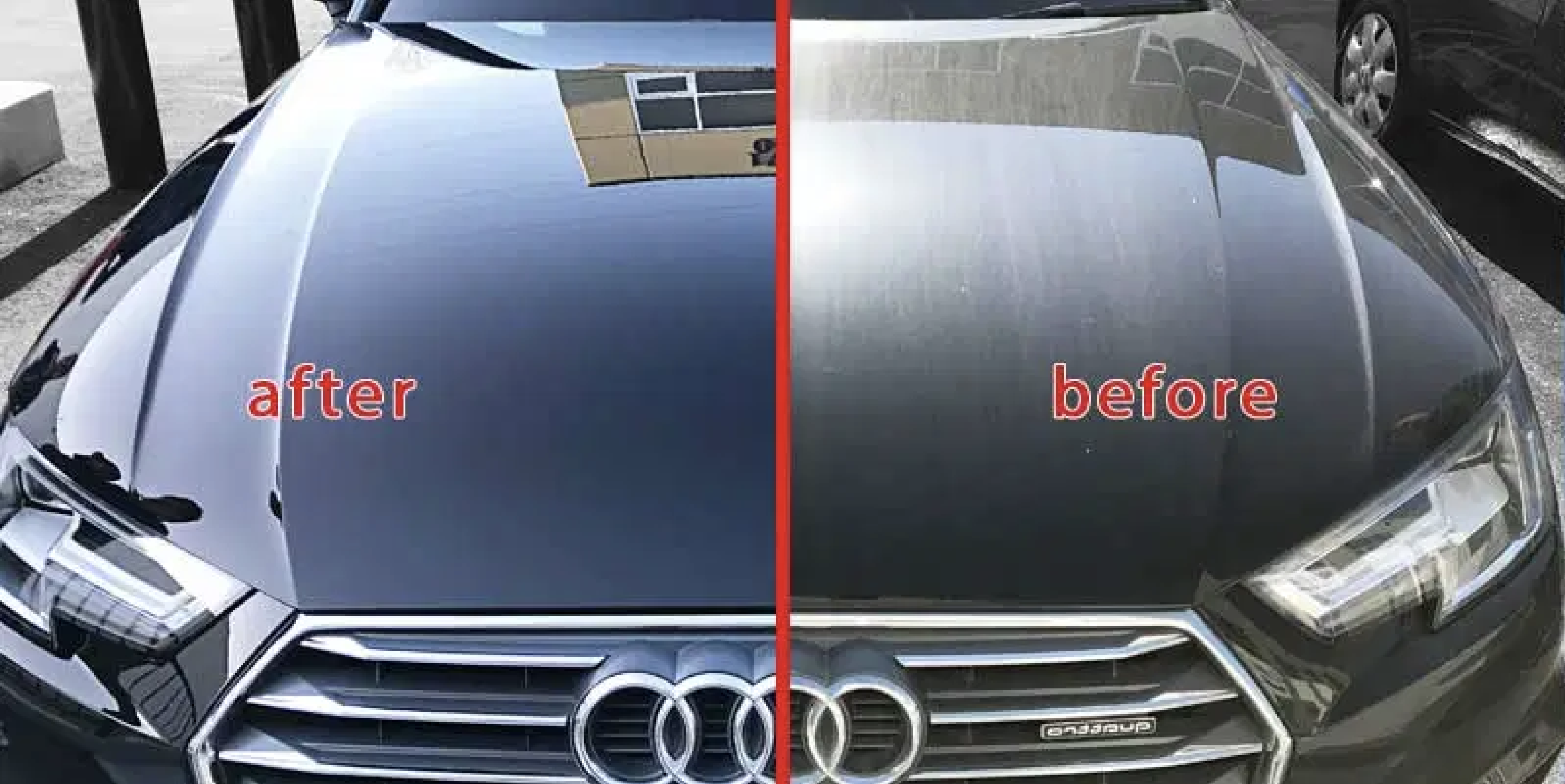

Ceramic finishings, in specific, offer various benefits that make them progressively preferred among manufacturers and customers alike. These coatings are immune to scrapes, chemicals, and UV rays, making sure that the underlying surface area remains safeguarded over time.

In addition to toughness, ceramic coverings offer superb hydrophobic residential properties, enabling easy cleansing and upkeep. This water-repellent nature minimizes the adherence of dirt, grime, and other contaminants, which can extend the visual charm and performance of the surface. Additionally, ceramic finishings can dramatically boost thermal resistance, making them optimal for applications that endure heats.

Application Process

When using ceramic layers, a careful strategy is important to accomplish ideal outcomes. A clean surface guarantees correct bond of the covering.

As soon as the surface is prepped, the next step is to apply the ceramic coating. The layer should be applied in slim layers, as thicker applications can lead to uneven surfaces.

After application, the finishing calls for a certain curing time, normally varying from a couple of hours to a complete day, relying on the item. Throughout this time, it is important to prevent direct exposure to moisture or pollutants. Ultimately, a mild buffing might be required after healing to improve the gloss and remove any kind of high places. Following these steps vigilantly will make the most of the effectiveness and longevity of the ceramic covering, offering a durable protective layer for the surface.

Upkeep and Long Life

To ensure the durability and effectiveness of a ceramic covering, regular upkeep is vital. Ceramic coverings, known for their durability and safety top qualities, page need specific care regimens to maximize their life-span and efficiency. The very first step in upkeep includes routine washing with pH-neutral soap, staying clear of harsh chemicals that can degrade the coating. It is advisable to wash the car consistently, ideally every 2 weeks, to avoid the build-up of pollutants that could compromise the finish's honesty.

In enhancement to routine washing, periodic inspections are important. Try to find indicators site of wear or damages, such as hydrophobic properties reducing or surface area imperfections. If required, a light gloss might be put on rejuvenate the finishing without removing it away.

In addition, the application of a booster spray can enhance the covering's hydrophobic impacts and restore its gloss. This is especially valuable for coverings that have been in use for a prolonged period. Eventually, by sticking to these upkeep practices, one can considerably expand the life of a ceramic covering, ensuring that it remains to offer ideal protection against ecological elements and maintain the visual charm of the automobile.

Conclusion